compression deflection test|durometer compression chart : solution Compression testing is a type of mechanical testing that involves applying a compressive force to a material and measuring its response. The compressive force tends to reduce the size of the material, and the test is designed to . WEBCruz Fox Official. Tiffany Mantovani ,cruz fox Richard castro. 37.4k 85% 5min - 1080p.

{plog:ftitle_list}

Resultado da 17 de jan. de 2024 · PowerBlock 是美國的健身器材品牌,主推可調式啞鈴 健諾克是 PowerBlock 的台灣代理商 PowerBlock 標示以「磅」為單位 50磅=23kg 70磅=32kg 90磅=40kg PowerBlock 不同系列的可調式啞鈴,還會各分成可擴充&無擴充版本 「Set」是無擴充版

Compression testing involves subjecting a material specimen or product to a controlled compressive force until it deforms or fails. The test can be either force- or strain-controlled and can follow either a constant ramp, a fixed waveform, or a random waveform.

Compression tests are used to determine a material’s behavior under applied crushing loads, and are typically conducted by applying compressive pressure to a test specimen (usually of either a cuboid or cylindrical geometry) using .

Compression deflection measures the force required to compress a known surface area over a controlled distance. In simpler terms, it is the force that the foam exerts back when in a compressed state. As you might imagine, this .

Compression testing is a type of mechanical testing that involves applying a compressive force to a material and measuring its response. The compressive force tends to reduce the size of the material, and the test is designed to .A compression test will help determine a material’s compressive yield strength, modulus and deflection under load—all characteristics that are critical to know.Deflection data can be obtained from compressive loading, thus from test types such as compression testing, shear testing, bend testing, and cyclic testing. A force-deflection curve is generated using data from the force transducer (load .Compression set testing is used to determine the ability of elastomeric materials to maintain elastic properties after prolonged compressive stress. The test measures the somewhat .

The purpose is to measure the spring’s compressive characteristics, such as its load-deflection relationship and spring rate. In this test, the spring is compressed between two platens, and the applied load and corresponding deflection are .A Practical Look at Compression Set: Effect of Temperature and % Deflection Stephen Seneker, Caleigh Elliott and Jordan Duckett Anderson Development Company 1415 E. Michigan Street Adrian, MI 49221 ABSTRACT ASTM D395 Method B (1) is the standard test method for evaluating compression set for a polyurethane. Originating in

This video shows how an ASTM D1056 compression deflection test is performed on an ADMET eXpert 7601 universal testing machine. Click more about ASTM D1056 te.ASTM D3574 C | Foam | Compression Testing. ASTM D3574 is a commonly used standard for tests involving flexible cellular foam materials. Section C specifies a method for measuring the compression force necessary to produce a 50% deflection over the entire top surface of the foam test specimen.Measuring the compressive strength of a steel drum. In mechanics, compressive strength (or compression strength) is the capacity of a material or structure to withstand loads tending to reduce size (compression).It is opposed to tensile strength which withstands loads tending to elongate, resisting tension (being pulled apart). In the study of strength of materials, .

Test C, called the compression force deflection test, is used to determine the amount of force necessary to produce a 50% compression over the entire area of a sample. This article describes an example case in which all three tests are .Resources » Glossary of Materials Testing Terms » Compression-Deflection Test . Discover simpler and smarter testing with features such as pre-loaded test methods, QuickTest in seconds, enhanced data exporting: and Instron Connect – a new feature that provides a direct communication link to Service. Users of previous versions of software .Compression set B is (like Compression set A) defined as the percentage of specimen deflection after it has been left in normal (uncompressed) conditions for 30 minutes. C B , the compression set B is given by C B = [(t o - t i ) / (t o - t n )] * 100 where t o is the original specimen thickness, t i is the specimen thickness after testing and . Test setup. In the bending flexural test, a specimen is loaded under uniaxial bending stress (tension and compression) in order to obtain information on the bending behaviour of materials.Especially brittle materials such as hard metals, tool steels and grey cast iron are tested in flexural tests. In such a bending test flexural strength, deflection at fracture .

moisture meter to detect leaks

Test D - Constant Deflection Compression Set Test; Test E - Tensile Test; Test F - Tear Resistance Test; While static tests provide valuable information regarding the initial foam properties and limitations, long-term dynamic testing provides manufacturers insight into the durability of the product. An end user expects foam products to feel .2 – Compression Deflection (25% Compression) 5 to 9psi, A1 – Change in Compression Deflection after aging for 22h at 100°C to be +/-30% from Original C.D., B2 – Compression Set at 23°C for 22h (50% compression) and after 24h recovery to be max. of 25%, E1 – Test method and values to be arranged by the Purchaser and the Supplier

ASTM D575 test method A is a procedure for determining the compression-deflection of rubber compounds (except hard rubber and sponge rubber). ASTM D575 is useful in comparing stiffness of rubber materials in compression. They can be used by rubber technologists to aid in development of materials for compressive applications. ASTM D575 test method A is a .

There are several ways the Vise can be oriented and aligned with available screw holes. This orientation should be determined by how the Compression Platen is expected to interface with the material specimen. 4. Install Material Specimen. The following material specimen installation is for a compression-deflection test of a 90-degree angle beam.

moisture meter units

Compression strength is evaluated through a test called Indentation Load Deflection (ILD), also known as Indentation Force Deflection. This is a computer controlled performance evaluation, with standardization allowing all materials tested using this process to be measured against each other on a balanced plane. Compression deflection is typically measured using a compression test, where a known force is applied to the foam PSA material, and the resulting deformation is recorded. ASTM D1056 is a standardized test method for measuring the compression deflection of cellular elastomeric materials. This test provides valuable data on the material's .The most common measurement obtained from a compression test is the compressive strength which is the maximum stress a material can withstand before it yields or breaks. It is also possible to measure modulus of elasticity, . Two of those characteristics or properties are compression deflection and compression set. Compression deflection is a measure of a materials resistance to force applied to a known surface area over a controlled .

The test is initiated by applying the load to the specimen at the specified cross-head strain rate. The deflection is measured either by a strain gauge under the specimen with contact in the middle of the support span, or by measuring the deflection of the test specimen. A load vs. deflection curve is plotted to determine the flexural modulus . Test C, known as the compression force deflection test, is utilized to identify the amount of force essential to produce a 50% compression more than the entire area of a sample. This article outlines an example in which all three tests are performed on polyurethane foam. Instrument and Fixtures. The test configuration is displayed in Table 1.Instron’s new 6800 Series systems are ideal for simple tensile and compression testing requiring only unidirectional force analysis. The system capacities range from 500 N to 300 kN and are capable of testing springs of most common sizes. . The standard options are to use a set load or deflection to indicate the end of the test, but this .The E-Series strain displacement deflectometers are often used for measuring deflection in 3 and 4 point bend tests, compression tests, and a variety of general test deflection measurements. The unit includes a magnetic base for easy mounting and a standard 25 pin connector.

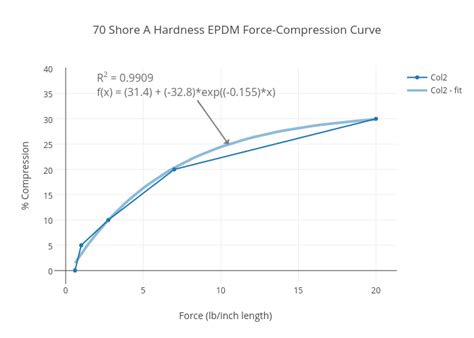

rubber durometer vs compression force

The purpose of the compression-deflection test is to compare the stiffness of the rubber materials under a compressive force. This test can tell you how much a part will deflect under a given load or, alternatively, how much load it will take to deflect a part a given distance. Rubber mounts and dampeners are some examples of parts that are . Compression force test procedures can be established to conform to ISO, ASTM, or other international standards, or the procedure may be developed in-house to achieve other goals. . Requirement for compression force measurement only, or force vs. deflection (travel) Interpretation and storage of results; Common Industry Examples: 1. Packaging .

•A RELATIVELY new test for preformed elastomeric joint seals is the compression deflection test. Its purpose is to measure the ability of the rubber seal to retain elastic properties and generate sealing forces after prolonged compressive stresses that might be encountered in actual use. Although this test is not an absolute indicator of .2 Compression Deflection (25% Compression) 5 to 9psi A1 Change in Compression Deflection after aging for 22h at 100°C to be +/-30% from Original C.D. B2 Compression Set at 23°C for 22h (50% compression) and after 24h recovery to be max. of 25% E1 Test method and values to be arranged by the Purchaser and the SupplierFinally, the grade rating is determined by the compression deflection given in PSI at 25% deflection. Unlike ASTM D3574, the sample for compression deflection testing for D1056 is much smaller. Solution: Compression Platens with a spherically-seated joint are required to perform these indentation force deflection (IFD) tests. Flexible cellular .Single-edge notch-bending specimen (also called three-point bending specimen) for fracture toughness testing.. The fracture toughness of a specimen can also be determined using a three-point flexural test. The stress intensity factor at the crack tip of a single edge notch bending specimen is [3] = [() / / + / / + /] where is the applied load, is the thickness of the specimen, is .

how to calculate rubber compression

forestry suppliers wood moisture meter

web1 de fev. de 2024 · AIDA64可以在连接到计算机的各种LCD/VFD设备上显示重要的系统数据。 最新的AIDA64版本支持超过50种LCD和VFD屏幕,并引入了对智能手机和平板电脑上传感器值的无线远程监控。 阅读更多 >

compression deflection test|durometer compression chart